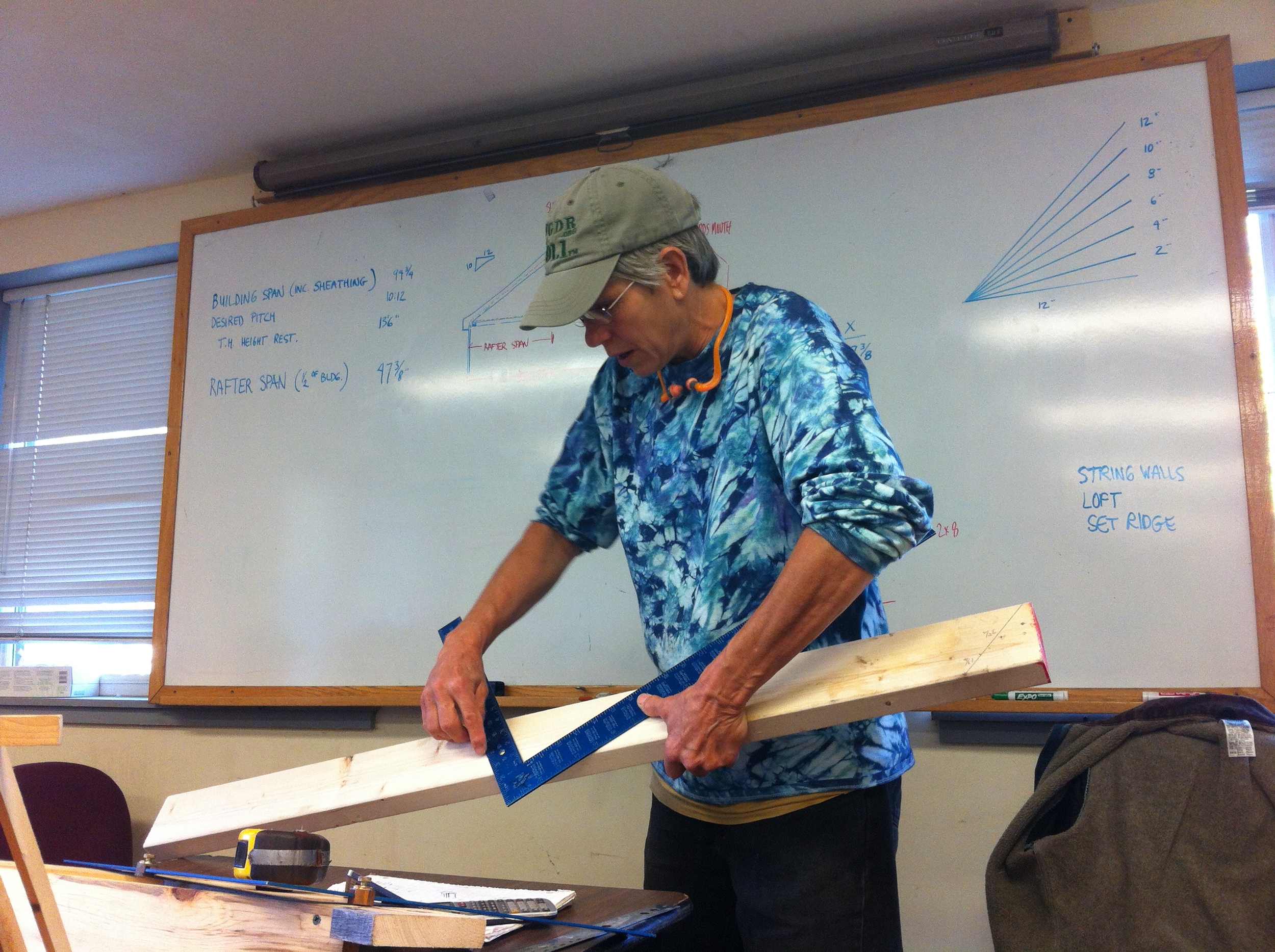

Patti started Day 9 of Yestermorrow's Tiny House Design-Build course with a presentation on roof framing. The tiny house on wheels we are building includes dormers in the center of the building, so we are cutting our rafters at two different pitches. Patti walked everyone through the vocabulary and structural mechanics of roof framing with models and diagrams. Then she demonstrated how to use a framing square to make bird's mouth cuts on the rafters. (See more photos in the Day 9 Slideshow.)

Patti started Day 9 of Yestermorrow's Tiny House Design-Build course with a presentation on roof framing. The tiny house on wheels we are building includes dormers in the center of the building, so we are cutting our rafters at two different pitches. Patti walked everyone through the vocabulary and structural mechanics of roof framing with models and diagrams. Then she demonstrated how to use a framing square to make bird's mouth cuts on the rafters. (See more photos in the Day 9 Slideshow.)

Down at the hanger we split into teams so we could square up the walls, build supports for the ridge beam, sheathe around the wheel walls, and begin cutting our rafters. The morning flew by and soon it was lunchtime. (I have resisted bragging about the incredible whole foods meal plan here, but let me assure you that the food is scrumptious at every meal!) I took the afternoon off from construction to have a nap and check in with Yestermorrow's office team. By the time I went down to the hanger the ridge beam was in place and most of the rafters were already up!

Since we only have two more days of design work the evening was devoted to studio time so everyone could work on their tiny house designs. However, most of them took breaks to join the festivities in Yestermorrow's dining room. It was a crisp evening, perfect for a jam night in the kitchen, accompanied by Cillian's famous popcorn and the ever-popular Heady Topper from local brewery, The Alchemist. The brew was courtesy of the tiny home's owner Day Benedict, who is a former Yestermorrow Intern. He came to meet everyone and see his little house. It was fun to get to know him and learn more about his plans for the tiny house. Between Dave Warren, Yestermorrow's Facilities Manager, and my co-instructor Patti we had a stand up bass and two guitars. We scrounged up some copies of Rise Up Singing and most of us sang along at some point to some good old folk songs (including one of my favorites: I'm My Own Grandpa). What a fun night!