Yesterday we worked on Ceiling Up My Vardo and today the plan was to continue work on both the roof and the windows. But today was one of those gray days that makes you suspicious from the start. According to the weather forecast there was only a 20% chance of rain, but it started raining while I drove my rental car to the build site in the morning. And actual rain, not just typical Portland spring showers. I hoped maybe that meant we were done with rain for the day. But I decided it wasn't worthwhile for us to attempt to work on the roof again, just in case.

Yesterday we worked on Ceiling Up My Vardo and today the plan was to continue work on both the roof and the windows. But today was one of those gray days that makes you suspicious from the start. According to the weather forecast there was only a 20% chance of rain, but it started raining while I drove my rental car to the build site in the morning. And actual rain, not just typical Portland spring showers. I hoped maybe that meant we were done with rain for the day. But I decided it wasn't worthwhile for us to attempt to work on the roof again, just in case.

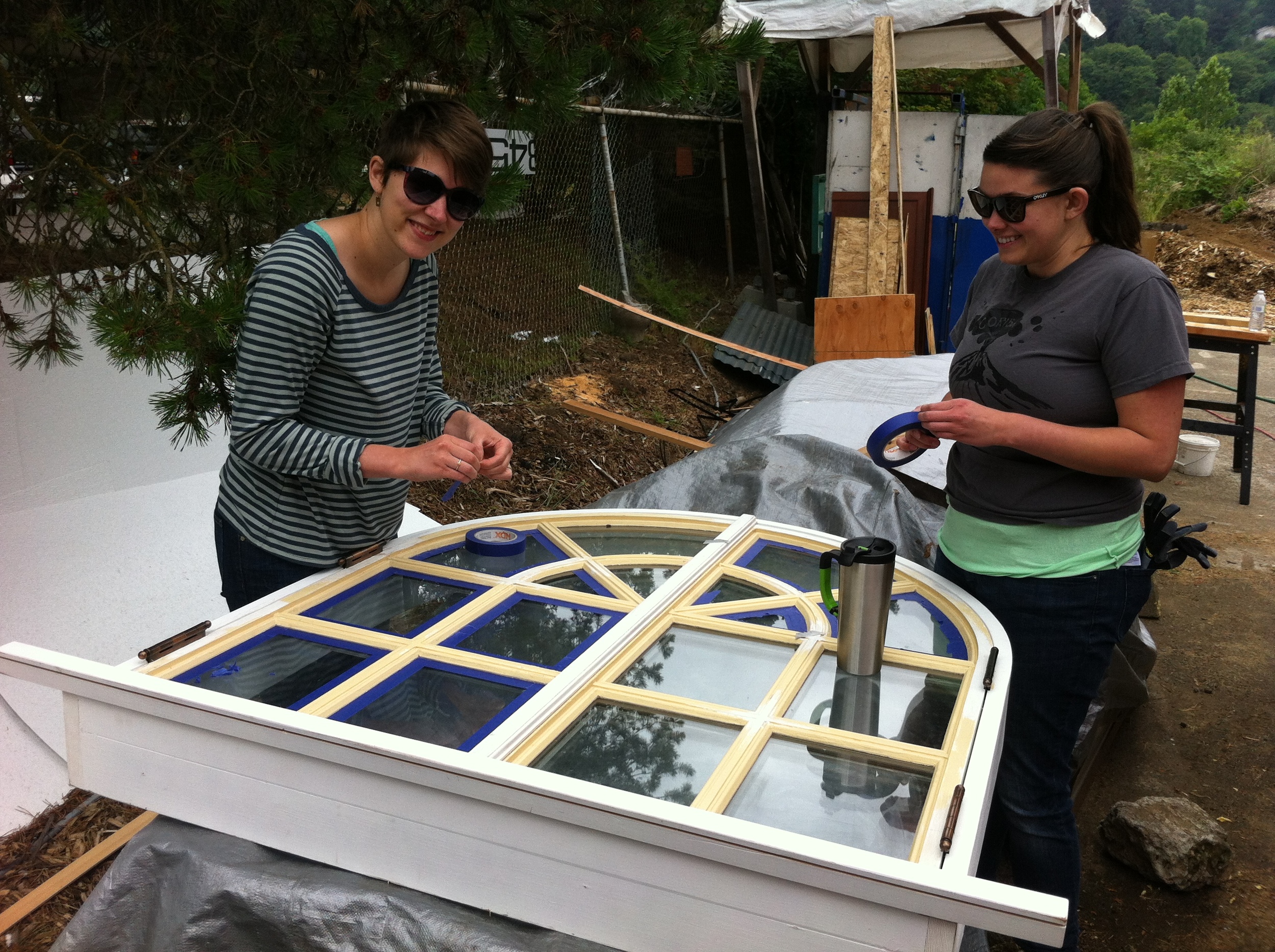

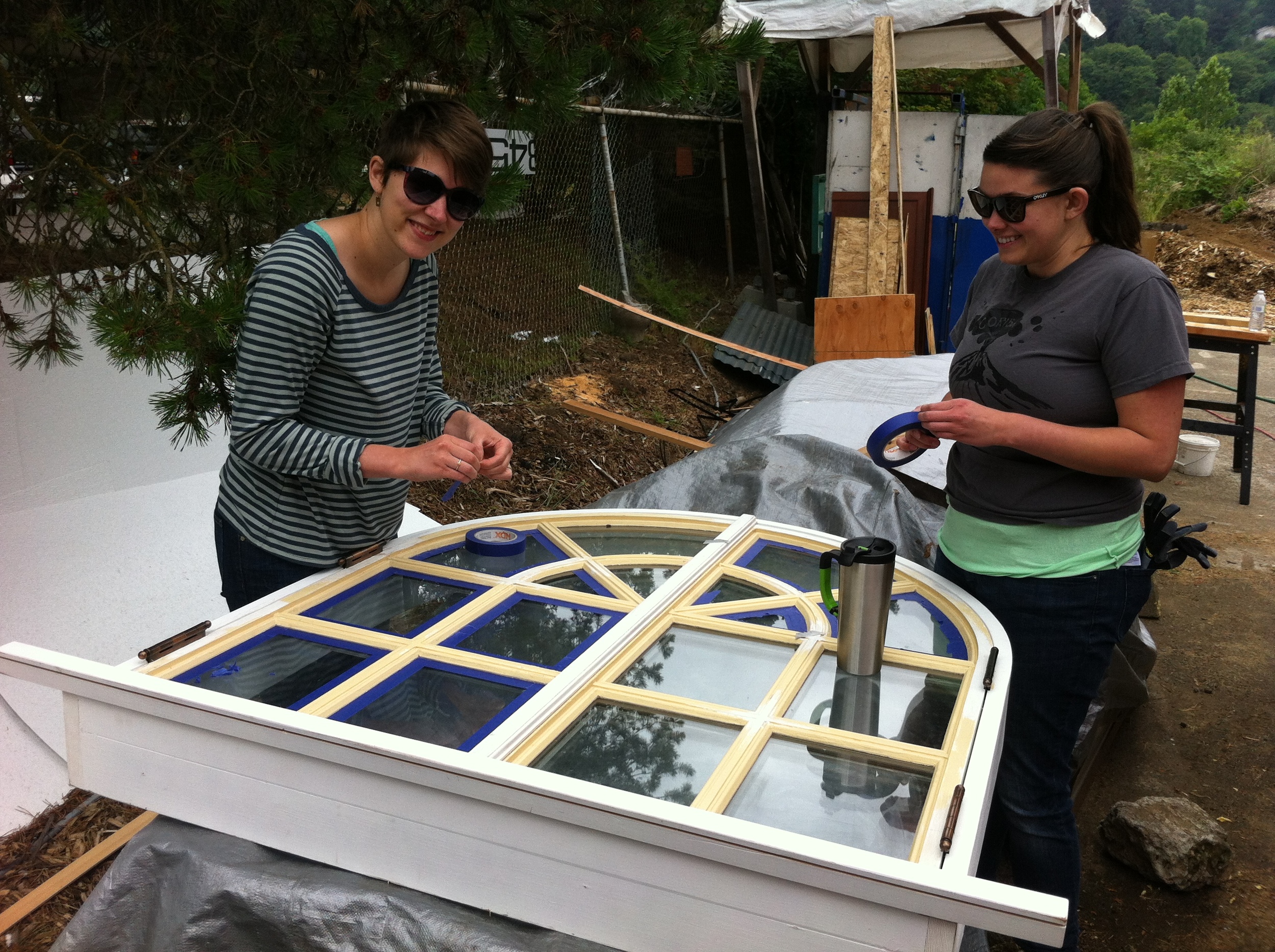

Instead Randy, Eleanor, Shelley, Matthew, and I worked on windows and door. Shelley and Eleanor did the most meticulous taping job I've ever seen in my life and then put the first layer of paint on the exterior of the arched window. Meanwhile Randy and Matthew worked on the door and I put a second coat of paint on the door jamb. It was almost lunchtime and Randy and I were sorting out pieces of varied trim I'd picked up from Green Star International when his rain-o-meter warned us that rain was imminent.

We had a lot of different materials out and realized we'd better get them put away. Eleanor and Shelley created a little tarp tent to protect the window they'd been painting and Randy and I threw tarps over the trim. We were hustling to put our tools away when that 20% chance of rain decided to arrive all at once.

Randy asked me if I wanted to tuck the Skylights for My Vardo inside, too. "No, they should be fine in the rain," I told him as we hurried under cover.

And they were fine with rain. But no so much with the wind. A gust of wind came up and caught one of the skylights and smashed it into the concrete, cracking the acrylic dome in several places.

I was crestfallen. Not only because I'd gotten a great deal on these skylights from Mark at Natural Light Skylight Co. And not only because I was pleased to have diverted them from the waste stream since they're salvaged. And not only because I'd already Painted My Skylight Frames. Actually, I was most upset that this was the second skylight I'd broken!

In January when my build buddy Laura Klement and I had been scouting materials for our tiny house builds, I'd come across a dome skylight at Building Material Resources. I checked it over and it was in great shape so I brought it home, only to discover the next morning that it was cracked. I must have cracked it somehow while moving it from the store to Laura's car to its temporary storage spot. In any case, it wasn't useable anymore so I took it to the landfill the next day since I was helping a friend with a dump run.

I hated thinking that I was contributing another skylight to the landfill that was in perfectly good condition before it came into my possession! I began wondering if it was a sign from the universe that my mollycroft roof was doomed. I'd already considered removing the skylights from my vardo twice, but couldn't bring myself to do it because I was so looking forward to the feeling they'd create inside. Fellow tiny house builders had encouraged me to stick to my dream. Now I was wondering if I should just give it up.

While I was wrestling with all of this frustration I was also attempting to appreciate that I had three really excellent people who had come to help me. We'd made good progress on the door and window. And here we were, all huddled in my house eating our picnic lunch while the rain - and hail! - battered my tarp. It was an adventure! And it was pretty cool being inside in the deluge! It will be really cool once I have skylights on the roof!

Nevertheless, we decided we were done for the day. So when Randy's rain-o-meter notified us of a relative dry spell from 1:12-1:23 pm we packed the trim away again (in no particular order - just like it had been before we sorted it!) I was afraid it would be floating in standing water since there were puddles everywhere, but it was actually relatively dry so we were able to get it put back just fine.

I was feeling grumpy and not quite sure how to rally. Fortunately, my build buddy Laura cheered me up by suggesting a trip to Sauvie Island. The rain had stopped by now (of course!) so we went to a u-pick strawberry farm. The berries were tiny and super sweet and the farm was beautiful so we had a great time picking pints.

Determined to make the most of the car rental, I ended my day by exploring several hardware stores and making a trip to Ikea. I enjoyed picking up a few supplies I needed and taking the time to wander the aisles to see if there were any new innovations I should be aware of.

Next weekend I'll be able to work on the tiny house all four days! So we should get the roof buttoned up and we may even get to start installing windows. I can't wait!